Tel:0086-574-6347 1043

Fax:0086-574-6347 1658

E-mail:hgjx@cxhgjx.com

Website:www.cxhgjx.com

Website:en.cxhgjx.com

Add:No.718, Weisan Road, industrial park, Andong Town, Hangzhou Bay New Area, Ningbo

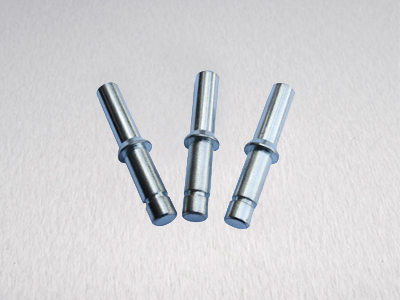

For the pin shaft fitting without inner hole or outer side, the rolling surface of the shaft or cover hole shall be coated with a layer of lubricating grease, and the needle shall be next to the lubricating grease at the equipment position. When sticking a needle, a gap should be left. The gap should be 0 in the circle of cylindrical roller bearing. 5mm is appropriate.

It is not allowed to squeeze a needle into the machine. Maybe a needle is missing, because the roller bearing will be stuck and can not rotate when it is hard squeezed. When it is missing, the gap is too large, which may cause the needle to twist and break when it is working. It must be noted that if the cylindrical roller bearing on the outer side of the stamping die is too thin for the outer wall of the pin shaft material to be hammered by hand, the press should be used to press in. Because of the uneven working pressure during hand hammering, part of the outer side of the cylindrical roller bearing is simply deformed.

The equipment is fully equipped with pin shaft universal joint, which is generally carried out in accordance with the specification of sleeve. At this time, the specification of the matching roller or the matching sleeve shall hold the needle to prevent it from falling out, the motor shaft shall scrape the needle due to its own fillet, follow the cylindrical roller bearing to move in the motor shaft gradually, and the specification of the matching roller or the matching sleeve shall withdraw gradually until it is put in the work direction.

The diameter of matching roller and matching sleeve shall be 0.1-0.mm smaller than the shaft diameter. When the equipment is installed, the outer inner surface of the rolling bearing shall be coated with lubricating grease, and the needle shall be placed against the inner surface. Then, the matching roller or matching sleeve which replaces the inner hole of the motor shaft or rolling bearing shall be sent to the outer hole wall, and the inner hole shall point to the inner hole of the equipment shaft or the inner hole of the rolling bearing on the shaft Hole, then press with punch or hand hammer.

The cylindrical roller bearing can also be used as such equipment. Apply a layer of grease to the specification and diameter of the matching sleeve, and sleeve it into the outer side of the rolling bearing, so that the specification of the matching sleeve and the outer side of the rolling bearing form a ring-shaped hole, and then install a needle on the ring-shaped hole. After installing the needle, use the working shaft to release the sleeve specification.