Tel:0086-574-6347 1043

Fax:0086-574-6347 1658

E-mail:hgjx@cxhgjx.com

Website:www.cxhgjx.com

Website:en.cxhgjx.com

Add:No.718, Weisan Road, industrial park, Andong Town, Hangzhou Bay New Area, Ningbo

There are many kinds of professional needle rollers in the work, which can be divided into copper rolling bearing, stainless steel bearing, composite joint bearing, etc. according to their raw materials; according to their moistening methods, they can be

It is divided into dry friction rolling bearing, oil bearing, incomplete floating oil rolling bearing, hydrodynamic film rolling bearing, etc.: our company now applies the lubrication method of rolling bearing

In order to not thoroughly lubricate the floating oil, several rolling bearings, such as copper, steel, copper base steel back self-lubricating, are successively applied. Copper rolling bearing has excellent ductility and resistance

General abrasiveness,

It has good maintenance effect on the shaft,

But the ability of deformation resistance is weak,

It is easy to deform during long-term application, which results in the inner of rolling bearing

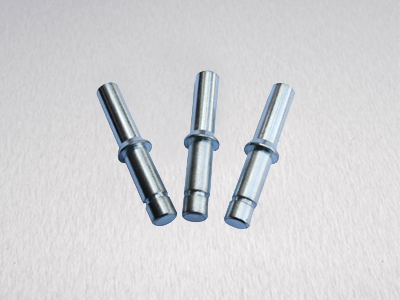

The processing technology of non-standard needle roller with high compressive strength, good wear resistance and deformation resistance, but surface conditioning treatment

High specification; copper base steel back self-lubricating bearing has the advantages of both steel rolling bearing and copper rolling bearing, in addition, oil groove lubrication and self-lubricating are closely combined,

The utility model can reasonably prevent the burning of the bearing needle, but the processing technology is complicated and the cost is high.

The design scheme of rolling bearing mainly considers the service life of rolling bearing,

The service life of the bearing is determined by the wear rate of the nominal diameter of the rolling bearing besides the burning.

The wear rate is mainly affected by the standard of friction, while the friction is also affected by the standard of load-bearing, rate, residue, surface roughness, operating temperature, different operating methods, applied lubricating fluid, etc. Therefore, the wear rate is only a basic theoretical estimate, and the service life of the shaft sleeve is taken as

It depends on all kinds of complicated standards. It is impossible to predict and analyze the damage condition if the residue penetrates and then the damage changes greatly due to the poor oil provided.

In general, the wear rate of copper rolling bearing (zcuall0fe3mn2) can be calculated by the above formula similarly:

W=K×P×V×T

W: Wear rate (mm)

K: Friction resistance [M M / (n / mm2 · M / min · HR)]

P: Bearing capacity (n / mm2)

5: Angular velocity (M / min)

T: Damage time (HR)

Where k = CI × K, K is the friction resistance under idealized condition, k = (1-5) × 10-8 [M M / (n / mm2 · M / min · HR)]