Tel:0086-574-6347 1043

Fax:0086-574-6347 1658

E-mail:hgjx@cxhgjx.com

Website:www.cxhgjx.com

Website:en.cxhgjx.com

Add:No.718, Weisan Road, industrial park, Andong Town, Hangzhou Bay New Area, Ningbo

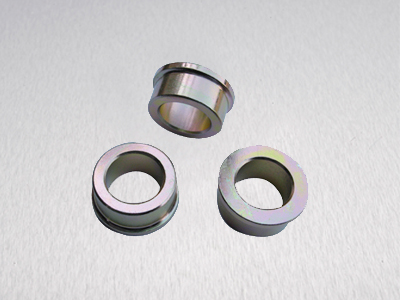

Cylindrical roller bearing cage is a component of the pull rod pin shaft, which is used to separate the needle and maintain the axial spacing of the roll. In most cases, the roller bearings are kept together. The holder can show the humidification according to the reservoir used as lubricating grease or according to the solid film produced by the holder raw material itself or the coating on the maintenance wall.

It is very important for the designer to choose a suitable cage design scheme to maintain the ideal service life and characteristics of rolling bearings. When the transparent holder shakes like a hula hoop, it causes a torque spike in the rotating parts. The transparent keeper should be traced on a real circular plan that is the same as the pitch diameter of the ball.

When the radial load is released to the static data rolling bearing whose axis is in the level mode, the needle reduces to the position where they are not evenly spaced before the load is released. When the radial load is released, the needle is extruded between the inner and outer dovetail guide rails. Now the ball is firmly held in place at the same pitch, and they cause the transparent keeper to fuse.

This kind of fusion is called "transparent holder offline". Once the pin shaft of the car starts to rotate, the transparent retainer will suffer ground stress, and some balls will deviate, leading to damage, which may lead to the invalidation of the rolling bearing too early. The installation site shall be away from CNC lathe, CNC grinder and other industrial equipment for a certain distance; the site shall be clean and tidy, always keep dry and impetuous cleaning, and firmly prevent the iron pin, small stone, dust and water from entering the cylindrical roller bearing.

Check whether the model and specification of needle bearing conform to the installation regulations, and select appropriate assembly line mode according to the structural characteristics of cylindrical roller bearing and each part matching with it, and prepare special tools and measuring instruments for pin shaft diameter installation in advance. Common installation workers have round head hammer, copper rod, sleeve specification, special cushion block, spiral mosquito tooling fixture, punch, etc., and measurement has micrometer, vernier caliper, dial indicator, etc.