Tel:0086-574-6347 1043

Fax:0086-574-6347 1658

E-mail:hgjx@cxhgjx.com

Website:www.cxhgjx.com

Website:en.cxhgjx.com

Add:No.718, Weisan Road, industrial park, Andong Town, Hangzhou Bay New Area, Ningbo

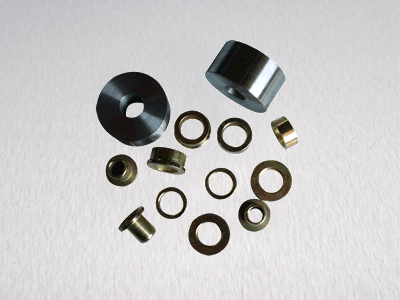

First of all, let's understand the basic structure of roller bearing material, which mainly includes rings, rollovers, cages and many other parts. Because the functions and mutual forces of each part are different, we should be particularly careful when using raw materials. We must consider the performance requirements of each component of cylindrical roller bearing.

1. Rings and rollover bodies of cylindrical roller bearings

When the cylindrical roller bearing comes from the running situation, one side of the pin shaft standard rollover body repeatedly bears high contact pressure, while the other side carries out the rolling touch accompanied by the drag.

From these aspects, the rings and rollover bodies of cylindrical roller bearings must be made of raw materials with good specification, reliability, high fatigue limit, high strength and strong friction resistance, which are generally made of high carbon steel chromium 45 steel. In addition, the main performance of raw materials in impact resistance, temperature resistance, corrosion resistance and other aspects must be considered according to different main uses.

If the specific provisions must be stronger impact resistance, chrome steel, chrome molybdenum steel, nickel chrome molybdenum steel can be selected as the rolling bearing raw materials, and after carburizing heat treatment, to promote the steel from the surface to the appropriate deep layer has a hard bottom layer, and further improve its impact resistance.

When some cylindrical roller bearings are made, vacuum pump is also used to remove air, so that the rolling fatigue life of rolling bearings is significantly increased, which is conducive to increase the service life of all cylindrical roller bearings.

2. Raw material of cage for cylindrical roller bearing

For pin shaft connection, one side of the cage is in contact with both sides of the ferrule and the rollover body, or one side of the cage is dragged; it also has the effect of anti tension and compression force. However, in the selection of raw materials, we have to contact the actual main use. If it is used for stamping die, low alloy steel is used as the raw material, and if it is net cage, high toughness copper, alloy steel and resin materials are all very good choices.