Tel:0086-574-6347 1043

Fax:0086-574-6347 1658

E-mail:hgjx@cxhgjx.com

Website:www.cxhgjx.com

Website:en.cxhgjx.com

Add:No.718, Weisan Road, industrial park, Andong Town, Hangzhou Bay New Area, Ningbo

The application of stainless steel needle roller bearing in CNC lathe is suitable for the following three positions: spindle bearing, ball screw and general rotating shaft.

As the basic assembly of CNC lathe, the characteristics of spindle bearing of machine tool immediately endanger the rotation speed ratio, rotation precision, rigidity, anti vibration processing, noise, temperature and thermal expansion of CNC lathe, thus endangering the precision and surface quality of processing parts. Therefore, the performance of CNC lathe must be suitable for the performance of rolling bearings.

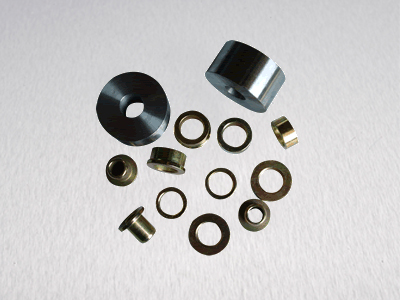

The precision of roller bearing is generally divided into five levels: P0, P6, P5, P4 and P2. The precision of roller bearing on the spindle of high-precision lathe should be P5 or above. For the spindle bearing support plate of high-speed and high-precision machines such as CNC lathe and CNC machining center, P4 or above leadership ultra precision bearing should be used.

The spindle bearing of CNC lathe generally consists of six structural features: deep groove ball bearing, angular contact ball bearing, cylindrical roller bearing, double investment angular contact ball bearing, deep groove ball bearing and thrust ball bearing.

With the rapid development trend of CNC machining technology of stainless steel needle rolling manufacturers, "composite, high-speed, intelligent, high-precision, environmental protection" has become the key development trend of CNC lathe industrial production technology. Among them, high-speed production and processing can reasonably improve the production and processing efficiency of CNC lathe and reduce the production and processing cycle time of steel parts. This stipulates that the lathe spindle and related components should be integrated into the requirements of high-speed production and processing. At present, the main shaft bearings of CNC machine tools are mostly limited to four structural features: angular contact ball bearings, cylindrical roller bearings, double investment angular contact ball bearings and deep groove ball bearings.

With the development trend of high-precision stainless steel needle roller spindle bearing to high-efficiency operation, structural ceramics (key refers to Si3N4 project ceramics) become the ideal raw materials for manufacturing high-speed precision bearings due to its low relative density, high elastic mold, small linear expansion coefficient, wear resistance, heat resistance, corrosion resistance and other high-quality characteristics. Ceramic bearings are more and more widely used. Due to the difficult technological performance of structural ceramics, high-precision ceramic bearings are often the mixed ceramic ball bearings which are made of porcelain and whose inner and outer rings are still made of chrome steel.

As a high-precision, high-efficiency and dexterous transmission system component, ball screw pair should not only select high-precision ball screw, nut and steel ball, but also pay attention to the use of high radial bending stiffness, small friction torque and high-precision running rolling bearing. In the past, ball screw support plate used to have double contact ball bearing, deep groove ball bearing, needle roller bearing and investment roller bearing combination bearing, deep groove ball bearing and thrust ball bearing. At present, the single row of contact ball bearing with 60 ° contact angle is selected as the most number of ball screw support plate. Moreover, the accuracy of roller bearing installed on the general rotating shaft for CNC lathe is also required. Its provisions and application are the same as that of the general gear driven rolling bearing. Only the compressive strength and service life provisions need to be considered, and the rotation speed ratio does not exceed the required limit rotation speed ratio of the rolling bearing Can.

Generally speaking, the machine tool bearing mentioned by people refers to the machine tool spindle bearing and its ball screw rolling bearing, while the high-precision machine tool bearing refers to the machine tool spindle bearing and ball screw rolling bearing with the precision of P5 and the superior leadership of P5.